Iron Ore Characterization Techniques in Mineral

2023年4月27日 Characterization tests are presented used not just for high-grade iron ores, but also for low-grade discard materials such as fines and tailings. While optical microscopy and SEM aid in micro-morphological

More

Comminution and classification technologies of iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct

More

Ore Crushing - SpringerLink

2023年7月22日 The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing. Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm.

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and

More

Measurement-Control for Crushing and Screening Process

2023年6月3日 Measurement-control for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable,

More

(PDF) GLOBAL TRENDS IN ORE HARDNESS

2015年9月1日 The SMC Test® has become one of the most popular laboratory tests for determining the ore hardness from an AG/SAG, HPGR and Crusher perspective. To date over 35,000 tests have been conducted.

More

Crushing characteristics and performance evaluation of iron ore in

In this study, the DEM (Discrete element method) bonded particle model is constructed to simulate the crushing process of iron ore based on the Apollonian sphere packing (ASP)

More

Numerical Study on Crushing Law of Iron Ore under Different

2021年10月1日 The results show that, with the increase of impact velocity, the fragments of iron ores increase gradually; The bottom ore is crushed most seriously, while the top ore is

More

Comparison of Ore Hardness Measurements for Grinding Mill

2021年1月14日 coating clearly yields the most accurate result with regard to the real density of ore in-situ in the mine or in a dry crushing circuit, but for grinding calculations where the ore is

More

Top 6 Steps Of Iron Ore Processing - Australian

2023年9月18日 To know more about this process and iron ore mining, contact us and learn all about iron ore, polyurethane, and the associated processes of processing iron ore. Stockpiling And Crushing. Before being crushed, the iron

More

How to design an iron ore processing facility with crushing and ...

2023年3月20日 1. Assess the physical properties of the ore, such as grade, mineralogy, hardness and variations within the deposit, as this will determine the process route.

More

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments. The primary objective of crushing is to reduce the ore size for subsequent processing and

More

Iron Ore - Minecraft Wiki

2024年10月27日 Iron ore generates in three batches. The first batch attempts to generate 90 times per chunk in blobs of 0-13 [JE only] or 0-16 [BE only], from levels 80 to 384, being most common around level 232 and becoming less common toward either end of the range.The second batch attempts to generate 10 times per chunk in blobs of 0-13 [JE only] or 0-16 [BE only],

More

Common Iron Ore Crushing and Screening Process - GeologyHere

Therefore, this process is a crushing process widely used in large and medium-sized iron ore concentrators. When dealing with argillaceous iron ore with high water content, or when restricted by terrain conditions, a three-stage open-circuit crushing and rod mill crushing process is sometimes used.

More

Iron Ore - Minecraft Wiki

Iron ore is a mineral block found underground. It is a source of raw iron, which can be smelted into iron ingots. Deepslate iron ore is a variant of iron ore that may generate in deepslate and tuff blobs. Iron ore itself can be obtained by mining it with a stone pickaxe or higher enchanted with Silk Touch. When mined without Silk Touch, iron ore drops raw iron. It is affected by the

More

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

2015年4月3日 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore. Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 8.5 % in basalt and gabbro.

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

More

What kind of crusher is good for crushing iron ore? Jaw crusher,

In the iron ore crushing process, a three-stage crushing process is generally adopted: coarse crushing, medium crushing, and fine crushing. ... mainly because the Mohs hardness of iron ore has reached 6.5 or above, which is a high-hardness metal ore, which has higher requirements for mining equipment, but it is not crushed and cannot be crushed.

More

Bond Work Index - an overview ScienceDirect Topics

Comminution. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Bond Tests. The most widely used parameter to measure ore hardness is the Bond work index Wi.Calculations involving Bond’s work index are generally divided into steps with a different Wi determination for each size class. The low energy

More

Crushing characteristics and performance evaluation of iron ore

2023年12月1日 Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al., 2014).The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the quality and performance of

More

Top 6 Steps Of Iron Ore Processing - Australian

2023年9月18日 To know more about this process and iron ore mining, contact us and learn all about iron ore, polyurethane, and the associated processes of processing iron ore. Stockpiling And Crushing. Before being crushed, the iron

More

Numerical Study on Crushing Law of Iron Ore under Different

PDF On Oct 1, 2021, Chun Feng and others published Numerical Study on Crushing Law of Iron Ore under Different Impact Velocity Using CDEM Find, read and cite all the research you need on ...

More

Iron (Fe) Ore Minerals, Occurrence » Geology Science

2023年5月7日 Iron (Fe) ores is a type of rock or mineral from which metallic iron can be extracted ... and has a hardness of 5.5-6.5. Other iron ore minerals, such as goethite, pyrite, and chamosite, may have different ... After extraction, iron ore is processed to remove impurities and obtain the desired iron content through crushing, ...

More

Iron Ore – Roll Crushing Technology redefined!

2024年1月15日 Iron ore (magnetite) with compressive strengths of up to 300 MPa was to be crushed as a secondary stage from a feed grain size of 0-300 mm to a final grain size of 0-80 mm. Our mobile CST 771 plant was used, equipped with the DRC series toothed roller, which was subjected to its hardness test here. The result was outstanding.

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

More

Processes for Beneficiation of Iron Ores - IspatGuru

2015年3月28日 Iron ores normally fall within one of the three categories namely (i) direct shipping, or high grade ores, which contain enough iron to be charged to the iron making furnace directly and may only require crushing, screening, and blending, (ii) associated low grade merchant ores which occur around the high grade ores that can be mined concurrently and

More

Iron Ore - Geoscience Australia

2023年12月19日 Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite ... Like hematite ores, magnetite ores require initial crushing and screening but also undergo a second stage of processing using the magnetic properties of the ore to produce a concentrate.

More

Exploring Low-Grade Iron Ore Beneficiation Techniques: A ... - MDPI

2024年8月2日 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient low-quality iron ore beneficiation to meet steelmaking quality requirements. This comprehensive review explores

More

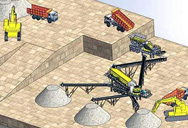

Crushing Plant Design and Layout Considerations - 911 Metallurgist

Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawal

More>> Next:Fournisseurs Mobiles Charbon De Concassage En Inde