Quartz Crushing Solution - Eastman Rock Crusher

Introduce how to crush Quartz, whole Quartz crushing plant flow layout (with photo), and related rock crusher machine. Contact us to do free flow design.

More

Quartz Processing Mastering the Art of Stone to Powder

2024年5月30日 FTM Machinery's quartz grinding production line follows ESG principles, minimizing crystalline silica dust exposure risk with efficient processes, ensuring employee and community health while balancing production

More

Quartz Crusher - Good Helper For Mining Construction

2024年4月12日 Quartz crusher is a machine used to process quartzite or quartz-bearing rocks into smaller particles, usually for mining operations or in the construction industry. This type of quartz rock crusher plays a vital role in

More

Quartz Crushing And Grinding Machine For Processing Plant

Crushing and grinding machines equipped with advanced technologies enable processing plants to achieve consistent particle sizes and control product quality with precision. This consistency

More

Enhancing Productivity With Quartz Grinding Machine

2023年11月28日 Quartz grinding mills serve as indispensable equipment in the processing of quartz, enabling the extraction of valuable particles for various industries. The commonly used

More

quartz crushing and grinding machine for processing plant

Investing in high-quality crushing and grinding equipment is crucial for any quartz processing plant looking to maximize its output potential while minimizing operating costs over time. The market

More

quartz crushing machine and grinding machine for processing plant

The quarts crushing and grinding process requires careful planning and execution with precision equipment tailored towards handling hard rocks effectively. It's crucial to choose a reliable

More

quartz crushing and grinding machine for processing plant

There are several machines available for quartz crushing and grinding in a processing plant. The primary machine used for quartz crushing is a jaw crusher, which can crush quartz into particles of varying sizes. After the initial crushing, a secondary crusher such as an impact crusher or cone crusher is used to further reduce the size of the ...

More

Quartz Ore - Ore Crushing Solutions - DSMAC

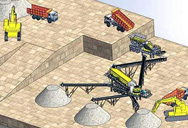

The quartz crushing and screening plant includes three stage: coarse crushing, fine crushing and sand making. Every stage has different quartz processing machine, in the coarse crushing,

More

Dolomite Sand Making Plant And Grinding Machine

2023年10月27日 Step 1: Turn Large stones into small stones. Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine

More

Quartz ultrafine grinding machine - EPIC Powder Machinery

High-end applications and processing technology of silica powder (ultrafine quartz powder), such as semiconductor chip packaging, copper-clad plate preparation, etc., are important areas of research and development at EPIC. EPIC’s ball mill classification production line,

More

Quartz Industrial Powder Grinder Machine - SBM Ultrafine

2021年10月11日 Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 150-3000 mesh. The industrial grinding mills independently developed and produced by SBM have the advantages of stable operation, high efficiency, energy-saving, and environmental protection, and long

More

How to Grind Quartz Crystals: The Ultimate Guide - 33rd Square

2023年10月19日 Feed raw quartz chunks into the jaw crusher either by hand or using a feeder belt conveyor. The movable jaw compresses the quartz against the fixed jaw crushing surfaces to fracture the material. Initially reduce quartz chunks down to less than 1 inch in size. Discharge crushed quartz from the bottom of the jaw crusher and collect for the next ...

More

Review on advances in mineral processing technologies suitable

2022年4月1日 Consequently, the degree to which a metal, mineral or material is considered critical, is determined by geopolitical factors that change with time (Spooren et al., 2020).For example, Australia has 24 “critical minerals” (Austrade, 2020) compared to the EU's 30 “critical raw materials” (European Commission, 2020).The EU has also seen an increase in the

More

quartz crushing and grinding machine for processin

quartz crushing equipment - eohlegalservices.co Equipment quartz crushing and grinding machine for processing plant Florence Baths stone production, construction, mining SKY is very proficient at the crushing, screening and grinding of iron ore, manganese ore, gold ore and copper ore etc. Learn More. mobile crusher for quartz spillerswharf.

More

What is Grinding Process How It Works – Different Types of Grinding

2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision. It is widely used in the machinery manufacturing industry. The heat-treated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically

More

Our Dynamic HPGR Technology for Mineral Grinding Weir

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore.. When it comes to feed material characteristics, the specific ore type is not detected by an Enduron® HPGR, however ore hardness, size and bed compressibility are important considerations.

More

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 1989-1996 (vols 203-210) 236(2):095440622211107

More

Graphite Ore Processing: Optimal Processes and Equipment

2023年5月12日 Graphite ore crushing (1) Raw ore feeding particle size: 300~500mm; (2) Final product particle size: 10~20mm; (3) The commonly used crushing process is a two-stage open circuit or a three-stage open circuit; (4) The equipment is a jaw crusher for primary crushing, a cone crusher, or a hammer crusher for final crushing.

More

Magnesite Ore Processing: Separation and Calcination

2023年5月12日 Quartz-magnesite separation process Reverse flotation is a commonly used method for separating magnesite and coexisting quartz. The processing flow is as follows. 1 Crushing: Crush the raw ore to 10-0mm with a

More

Mineral Processing Equipment for Mining Industry

2024年8月7日 Grinding Equipment: After crushing, grinding refines ore into a fine powder to liberate valuable minerals. Key types include Ball Mills, which grind ore using steel balls in a rotating cylinder; Rod Mills, which use long rods for a coarser grind; and SAG Mills, which combine crushing and grinding for efficient processing of large volumes of ...

More

Silica Sand Processing Plant - JXSCTeam

Silica quartz stone crushing and screening process The raw silica quartz stone enters the jaw crusher for primary crushing. ... The crushed silica goes to a grinding machine for grinding to separate it from impurities as much as

More

Enhancing Productivity With Quartz Grinding Machine

2023年11月28日 Waste Minimization: By implementing efficient grinding techniques, a processing plant minimizes waste generation and optimizes resource utilization. Quartz Grinding Machine Types. Quartz grinding mills serve as indispensable equipment in the processing of quartz, enabling the extraction of valuable particles for various industries.

More

Crushing Plant Flowsheet Design-Layout - 911Metallurgist

2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise. Crushing Plant Flowsheet

More

Feldspar Mining Process Equipment Flow Cases - JXSC

1. Crushing and grinding The crushing and grinding of feldspar are not only to meet the grain size requirement of the final product, but also to meet the need of the impurity removal process. The coarse crushing of feldspar mostly adopts jaw crusher, and the particle size is about 10mm.

More

process for crushing quartz

Quartz powder processing mill with vertical or Raymond mill Quartz powder processing mill stand: stand mill is the latest development of a set of crushing, drying, grinding, separator, one of the efficient delivery of lowenergy grinding machines, high grinding efficiency, low energy consumption, bake dry capacity, product fineness is easy to adjust, the process is simple and

More

What is the machine for processing quartz stone?

What is the machine for processing quartz stone? Processing quartz stone typically requires a series of machines to complete the various stages of crushing, grinding, and purifying. Here are some of the key machines used in the processing of

More

Crushing and Grinding Process - JXSC Machine

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption. In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as

More

Quartz Crusher - Good Helper For Mining Construction

Find the best quartz crushing solution for your mining and construction projects. Skip to ... Quartz crusher is a machine used to process quartzite or quartz-bearing rocks into smaller ... which is a rotating cylindrical drum filled with steel balls or other grinding media. As the drum rotates, the balls crush the quartz into a fine powder ...

More>> Next:Ciment Broyeur à Boulets Site De La Mine Photo