Coal mill pulverizer in thermal power plants PPT

2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants. It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to

More

HOW ELECTRICITY IS PRODUCED AT A COAL-FIRED POWER

Inside the power station, the coal is pulverised to a fine powder in giant grinding mills. This is because pulverised coal burns quickly, like gas. The pulverised coal is transported to the boiler

More

Coal Pulverizer – Power Plant Pall Corporation

Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise most coal pulverizers currently in service at pulverized coal power plants. The grinding rolls are stationary in this design, while a worm

More

An investigation of performance characteristics and

2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency. Uniform coal feeding mass flow rate and required particle...

More

Instrumentation and control in coal-fired power plant - ICSC

Coal-fired plants are the most widely used power plant today. They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature

More

Derivation and validation of a coal mill model for control

2012年5月1日 The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of power plants

More

Coal-Fired Power Plant Designs, Systems, and Components

are three primary designs for utilizing and combusting coal in EGUs. The current dominant design is a pulverized-coal (PC) unit, in which coal is ground via a pulverizer to a fine powder and

More

Expert systems and coal quality in power generation - USEA

Coal quality, that is the properties of coal, has an impact on many parts of a power plant including the coal handling facilities, pulverising mills, boiler, air heater, ESP, ash disposal as well as

More

A unified thermo-mechanical model for coal mill operation

2015年11月1日 Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills. In this paper, a dynamic

More

Pulverised Coal Flow measurement in Thermal Power Plant

estimate the pulverised coal flow using real time on-site plant data. 2. COAL MILL MODELLING In thermal power plant, pulverization of coal is carried out by coal mill. Raw coal is moved from the storage to the mill by conveyor mechanism. The type of coal mill envisaged for our model is bowl mill which is shown in Fig.1.

More

Pulverizer - Wikipedia

Beater wheel mills are designed to prepare a coal powder air-fuel mixture for combustion in furnace chambers of coal-freed power plants by coal drying, pulverizing, classifying and transport. Their multipurpose function usually results in operation instability accompanied by

More

Coal Mill in Thermal Power Plant: Enhancing Efficiency and

These mills are typically used in thermal power plants to grind coal to the desired fineness, facilitating efficient combustion and maximizing the generation of electricity. Bellian Machinery's coal mills are engineered to meet the specific requirements of thermal power plants, ensuring reliable and efficient operation.

More

Use of coal - U.S. Energy Information Administration (EIA)

Many industries and businesses have their own power plants, and some use coal to generate electricity for their own use, mostly in combined heat and power plants. In 2022, coal accounted for about 19.5% of U.S. electricity generation. Coal use by industry.

More

Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal ...

Coal mills, also known as pulverizers, play a critical role in power plants by grinding coal into fine powder, which is then used in various pyroprocesses. Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal Mill Safety, Explosion and Fire Protection Consultancy

More

Boiler Mill and Coal Pulverizer Performance GE Steam Power

Can GE service my boiler mills?. YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities.We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions.This is the Power of Yes.

More

Thermal desorption of mercury from lignite in a high-temperature ...

2022年9月27日 Furthermore, the question arises whether mercury is already released during the grinding-drying process in the coal mill of a power plant. At two power plants, lignite samples were taken simultaneously at the feeder before entering the coal mill and at the dust line afterwards. The samples were analyzed for mercury concentration. The results ...

More

Expert systems and coal quality in power generation - USEA

a power plant including the coal handling facilities, pulverising mills, boiler, air heater, ESP, ash disposal as well as stack emissions. Figure 1 is a diagram of a typical pulverised coal combustion power station. Table 1 is the stages that require monitoring in a coal-fired power generating plants (as shown in Figure1).

More

What is the role of a mill in a coal-fired power plant?

2023年11月30日 In a coal-fired power plant, a mill or pulverizer plays a crucial role in the process of converting raw coal into a form that can be burned efficiently and used to generate electricity.

More

Coal Power Plants in Pakistan (Map) database.earth

Coal is predominantly used as fuel to generate electric power in coal-fired power plants. Where bituminous coal, subbituminous coal, or lignite is burned to generate elecricity. In coal-fired power plants the heat produced by the combustion of coal is used to convert water into high-pressure steam, which drive turbines that produces electricity.

More

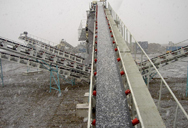

Coal handling plant in a thermal power generating

2013年7月17日 In a coal based thermal power plant, the initial process in the power generation is "Coal Handling'. Boiler used in the power plant is suspended type. for: Home; Membership; ... Coal is transported to bowl mills by

More

List of coal-fired power stations in the United States - Wikipedia

Coal generated 16% of electricity in the United States in 2023, [1] an amount less than that from renewable energy or nuclear power, [2] [3] and about half of that generated by natural gas plants. Coal was 17% of generating capacity. [4] Between 2010 and May 2019, 290 coal power plants, representing 40% of the U.S. coal generating capacity, closed.

More

An investigation of performance characteristics and

2020年8月12日 As the significant ancillary equipment of coal-fired power plants, coal mills are the key to ensuring the steady operation of boilers. In this study, a fault diagnosis model was proposed on the ...

More

INVESTIGATION ON CLASSIFICATION EFFICIENCY FOR COAL-FIRED POWER PLANT

angle on the classification efficiency in Coal-Fired power plants. The gas flow inside the coal mill was solved by the realizable k -ε turbulence model (RKE) with a detailed 3-D classifier geometry meanwhile the discrete phase model was used to solve the coal particles flow. The steepest classifier blade angle of 40 o achieved

More

Thermal Power Plants: Components Working Principle

2020年6月3日 Advanced Coal-fired Power Plant . Super critical (SC): 540-580 o C and 22.1 – 25 Pa. Ultra super critical (USC): ... The country has 87 sugar mills with a generation capacity of 3000 megawatts from bagasse in the winter. Currently, 7

More

Exergy Analysis and Efficiency Improvement of a Coal Fired

2013年4月17日 2. Process description of a coal-fired power plant. A coal-fired power plant burns coal to produce electricity. In a typical coal-fired plant, there are pulverisers to mill the coal to a fine powder for burning in a combustion chamber of the boiler. The heat produced from the burning of the coal generates steam at high temperature and pressure.

More

classifications and working of mills in a power plant PPT

2020年6月29日 COAL MILL PERFORMANCE TEST The pulverisers are the “heart” of a pulverized coal fired power plant and as such, must be set up for maximum effectiveness so that the best furnace performance can be achieved. Poor mill performance affects combustion , boiler losses , heat rate of unit , capacity of unit , APH , ESP performance , aux power.

More

Instrumentation and control in coal-fired power plant - ICSC

Coal-fired plants are the most widely used power plant today. They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature (>500ºC) steam which is used to drive a turbine at synchronous speed (3000 rpm in countries such as the UK with a 50 Hz supply frequency, 3600 rpm in ...

More

Detection of Malfunctions and Abnormal Working Conditions of a Coal Mill

2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns. Therefore, an algorithm has been developed that enable online detection of abnormal conditions and malfunctions of an operating mill. Based on calculated diagnostic signals and defined

More

The layout of the coal mill with a rotary classifier.

This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coal-fired power plant. In a power plant, the coal mill is the critical equipment, whose ...

More>> Next:Broyage De Calcaire De Qualité