Portable barite grinding mills: Versatile and efficient solutions

Portable barite grinding mills are compact and portable versions of the traditional ball mills. These mills are specifically designed for grinding barite into fine powders, meeting the precise

More

Exceptional Barite Processing Methods and Machines

2023年3月20日 To fully dissociate useful barite minerals, ball mills are commonly used to grind barite rocks. Generally, the grinding fineness of barite-200 is 85~90%, and a two-stage grinding process is often used. In view of the

More

Quantifying of particle shape differences of differently milled

2019年12月1日 In this study, shape analysis of barite mineral ground by various mills (ball, rod and autogenous) that are widely used in mineral processing, were achieved by the recent

More

The effects of ball filling and ball diameter on kinetic breakage ...

2012年9月1日 The absolute fineness of the ball diameter and the ball charge grading are important factors for the optimal operation of a ball mill. Therefore, the effects on breakage

More

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the

More

BARITE GRINDING MILLS - Williams Crusher

The engineers at Williams Patent Crusher design and manufacture various barite grinding mills that can accomplish the appropriate size reduction needed for your application. Barite, or baryte, is the mineral consisting of barium sulfate and

More

MQ Series Ball Mill - Zenith Crusher

Ball Mill is mainly used in metallurgy, chemical engineering, electricity, cement and other industrial and mining enterprises to grinding all kinds of ores and other grindable materials. It can grind limestone, calcite, marble, talcum, dolomite,

More

Ball mill characteristics and test conditions

The kinetics of batch dry and wet grindings of calcite, barite, quartz, lignite and anthracite from feeds of sieve size - 425+300 μm has been determined using a laboratory scale ceramic ball...

More

_Taurus - Ball Mill - NETZSCH Grinding Dispersing

NETZSCH Taurus Ball Mill, the pinnacle of fine and ultra-fine grinding technology. Achieve precise particle sizes with durable, low-maintenance equipment.

More

The effects of ball filling and ball diameter on kinetic breakage ...

2012年9月1日 Deniz (2012) in his dry ball mill studies investigated the impacts of media filling on the kinetic breakage parameters of a barite sample, and he found out that the filling ratio of 0.35 was a ...

More

The effects of ball filling and ball diameter on kinetic breakage ...

2012年9月1日 DOI: 10.1016/J.APT.2011.07.006 Corpus ID: 137124436; The effects of ball filling and ball diameter on kinetic breakage parameters of barite powder @article{Deniz2012TheEO, title={The effects of ball filling and ball diameter on kinetic breakage parameters of barite powder}, author={Vedat Deniz}, journal={Advanced Powder Technology},

More

Ball Mill Steel Balls: Quality And Gradation - JXSC

2024年2月19日 The ratio of steel balls in the ball mill depends on the effective length of your mill, whether it has a roller press, the size of the feed particles, the lining and structure used, the expected sieve residue fineness and ratio, how

More

Flotability of barite particles with different shape and roughness

2007年11月1日 In this article, different mill (ball, rod and autogenous) products of barite mineral were characterized in terms of their shape, roughness and wettability. 2D shape parameters were measured by ...

More

Small Gypsum Graphite Barite Cement Power Ball Mill Grinding

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different

More

Ore Grid Cone Ball Mill Equipment for Potash Feldspar, Barite,

Ball mill is the key equipment for grinding after crushing Widely used in mineral processing, building materials and others.Ball mill can divide into 2 types, wet ball mill and dry ball mill. Ball mill is a mineral processing machine for milling the materials into powders after they are crushed.

More

Barite Beneficiation Process and Plant Flowsheet

2016年4月9日 Barite-Fluorspar-Zinc Ore Grinding. The ore for treatment is of such a nature that conventional grinding to —65 mesh using a ball mill classifier circuit results in excessive overgrinding of the barite. To avoid this condition a rod mill is used instead of a ball mill for reducing the feed for flotation.

More

How an Overflow Ball Mill Works? - JXSC Mineral

2023年4月27日 Overflow Ball Mill Type. Overflow ball mill equipment– short tube ball mill The cylinder length L is less than twice the cylinder diameter D. The ball mill with L≤2D is a short cylinder ball mill, mostly with a single chamber structure, mainly used for rough grinding or primary grinding in mineral processing plants.

More

Ball mill characteristics and test conditions Download Table

This paper presents the kinetics study of dry ball milling of calcite and barite minerals. The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total ...

More

Ball Mill Maintenance Process and Methods - Mining-pedia

When maintaining the ball mill, the following tools and equipment may be helpful: 1. Wrench: used to disassemble and install fastening bolts, nuts, and other components.. 2. Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts.. 3. Lubricating oil: selecting appropriate lubricating oil is crucial for ball mill maintenance.

More

The Effects of Ball Types on Breakage Parameters of Barite

Keywords: ball mill, ball type, barite, breakage parameter Introduction Barite is being produced in various region of Turkey, mainly in Adana, Konya, and Isparta that is widely used as oil drilling, painting, paper and plastic sector, etc. In these industries, grinding of barite mineral is

More

Tower Mill Operating Work Index - 911Metallurgist

2016年6月3日 The Tower mill can be installed for a fraction of the cost of an equivalent kilowatt (horsepower) ball mill. The Tower mill develops very little dynamic forces. Therefore, ... Barite from 2.8 microns average to 1.55

More

Population balance modeling approach to determining the mill

2022年1月1日 In the past, most of the Population Balance Model-based ball mill scale-up studies were carried out using a mono-size ball charge and a single size fraction of the particulate material as the starting feed. It was reported that the breakage distribution parameters were independent of the mill diameter, specific breakage rate parameters varied with mill diameter

More

Quantifying of particle shape differences of differently milled barite ...

2019年12月1日 In this study, shape analysis of barite mineral ground by various mills (ball, rod and autogenous) that are widely used in mineral processing, were achieved by the recent developed technique, namely; DIA and quantified shape differences by created different grinding in terms of the most common the shape parameters, namely; circularity (C) and bounding

More

Ball Mill Steel Balls: Quality And Gradation - JXSC Mineral

2024年2月19日 The ratio of steel balls in the ball mill depends on the effective length of your mill, whether it has a roller press, the size of the feed particles, the lining and structure used, the expected sieve residue fineness and ratio, how many chromium balls to operate, and the rotation speed How much and other factors make a comprehensive judgment.

More

Particle size distributions of barite and quartz minerals ground

Download scientific diagram Particle size distributions of barite and quartz minerals ground in different mills determined by sieving: (a) ball-milled barite, (b) rod-milled barite, (c) ball ...

More

Ball Mill - SBM Ultrafine Powder Technology

Ball mills can be used for dry or wet grinding of various ores and other grindable materials. It has stable operation, reliable operation, large production capacity +8617821848717 [email protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech. Co., Ltd. Home; About Us;

More

Barite - Jam Group Company

After the barite has been crushed and screened, it goes into a fine powder using various grinding methods, such as ball mills, hammer mills, and rod mills. The ground barite is then classified according to particle size, and the desired particle size

More

Barite (Baryte) Beneficiation Process - JXSC Mineral

Barite is a mineral composed of barium sulfate. The main barite beneficiation are gravity separation, magnetic separation, and flotation. Skip to content. JXSC Mineral. ... vibrating screen, ball mill, classifier, stirring tank, flotation machine, magnetic separator (used to remove iron impurities) ), concentrator, dryer, etc. Barite ...

More

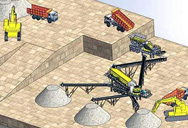

Barite processing plant, barite quarry and mining equipment

Jaw barite crusher is used for coarse, medium and fine crushing. After primary crush by the barite crushers, you can install barite grinding machine which is decided according to the final particle size requirement. For barite further grinding, there are Ball Mill, Raymond Mill, Coarse Powder Grinding Mill, etc.

More>> Next:Instruction De Travail Pour Le Broyage De La Main Results