J-1170 Stone Crusher Mobile Jaw Crusher Terex Finlay

The Finlay® J-1170 Stone Crusher is a compact and aggressive tracked jaw crusher. The heartbeat of the machine is a robust hydrostatically driven Terex jaw chamber which provides

More

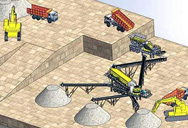

Crushing and Screening Handbook - AusIMM

all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all secondary, tertiary or quarternary crushing ap-plications. High performance ...

More

(PDF) Development of a New Generation High

2023年12月31日 The design and development of a new generation high crushing capacity jaw crusher, developed for the first time in Turkey and whose Closed Side Settings (CSS) may be automatically adjusted ...

More

A Guide to Types of Jaw Crushers for Crushing Rocks

2023年2月15日 Discover the most common types of jaw crushers used in the stone crushing industry, including single toggle, double toggle, Blake, ... It has a high crushing capacity, and it is easy to operate and maintain. ... +86

More

Stone Crusher Manufacturing Equipment in Kenya - Jiji.co.ke

Type of stone crushers for sale. Jaw crusher machine Impact crusher Small Hammer Crusher and Heavy ... The Nile stone and ore crushing production line features in high automation, high crushing ratio,... KSh 770,000 ... 80 to 1000 tons per hour Crushing Capacity "we have corresponding warehouses and technicians in ...

More

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported

More

Modtec: Stone Crushing Machines In Kenya/ Jaw Crusher

Stone Crushing Machine helps in crushing stones into smaller desirable size depending on the project the stones are intended to be used in A crusher is a machine ... We are a professional manufacturer of stone jaw crusher for more than ten years in Kenya. We manufacture and supply jaw crusher. All our products have high quality and reasonable ...

More

Jaw Crushers, For Stone, Capacity: Upto 300 Ton Per Hour

Royal Engineering - Offering Jaw Crushers, For Stone, Capacity: Upto 300 Ton Per Hour at Rs 1100000 in Sabarkantha, Gujarat. Also find Jaw Crusher price list ID: 18073143230

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Primary crushing is the first stage of the stone crushing process. At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing. The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers. Jaw Crusher

More

Choosing the Right Jaw Crusher Size and Capacity for Optimal

2023年2月28日 Maximizing crusher performance and productivity requires selecting the right jaw crusher size and capacity. ... Our expert guide provides valuable insights and recommendations for achieving the best possible results. Skip to content. Call Us Now: +86 13683722138 . Email: info@crushing-machine. ... 450t/h Stone Mobile Crushing Plant;

More

PE250x1000 PE250x1200 Jaw Stone Crusher Machine

High quality PE250x1000 PE250x1200 Jaw Stone Crusher Machine from China, ... Comparing with traditional jaw crusher, it has larger capacity and crushing ratio, bigger range of input size, evener product size, and easier maintenance. Features of Stone Jaw Crusher 1. High crushing ratio, well-distributed final product size. 2.

More

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported

More

J-1170 Stone Crusher Mobile Jaw Crusher Terex Finlay

The Finlay® J-1170 Stone Crusher is a compact and aggressive tracked jaw crusher. The heartbeat of the machine is a robust hydrostatically driven Terex jaw chamber which provides high capacity with large reduction ratios.

More

Stone Crusher - Rock Crushing Machine

As the material is fed into the crusher, the movable jaw presses it against the fixed jaw, crushing it into smaller pieces. impact crushers work by using high-speed rotors that throw stones against hard surfaces, creating fractures upon impact. cone crushers break down stones by squeezing them between a rotating mantle and a stationary concave, while hammer crushers use high

More

High-Quality Mobile Jaw Crusher For Efficient Stone Processing

Processing capacity: 250tph Configurations: 4 in 1 mobile unit, including mobile jaw Crusher, mobile cone crusher, and mobile screener, etc. Project: road construction Customer feedback: “I’m absolutely thrilled with AIMIX’s mobile jaw crusher for processing limestone!It exceeded all my expectations. The crusher‘s efficiency in crushing limestone is exceptional, delivering

More

Stone Crusher Machine Price: Factors, Range, and Ways to Save

2023年2月28日 High-quality machines are generally more expensive than low-quality ones. Production capacity: The production capacity of a stone crusher machine refers to the number of tons of material that can be crushed in a specific time period. Higher production capacity machines are generally more expensive than low capacity ones.

More

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

More

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW

2017年6月30日 Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing.

More

Problems with Toggle Plates in Jaw Crushers and How to Fix Them

2023年2月16日 This blog post provides valuable information on the common problems that can arise with toggle plates in jaw crushers and how to fix them. It offers detailed explanations of the solutions for issues such as broken or loose toggle plates, worn toggle plates, misaligned toggle plates, and damaged tension rods. By following the manufacturer's recommendations for

More

Jaw Crusher for Sale in Indonesia-- Primary Stone Crusher

Jaw crusher Indonesia is the preferred device of the primary crushing. Primary jaw crusher has the characteristics of high crushing ratio, uniform product size, simple structure, stable working performance, easy maintenance, economic operation cost, etc. Stone jaw crusher is widely applied to the mining, smelt, construction materials, highway, railway, conservancy and

More>> Next:Broyeur à Boulets De Conception Standard