How Does a Jaw Crusher Work - Kemper Equipment

2022年6月8日 All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is

More

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 Discover everything you need to know about jaw crushing machines, from the various types such as single and double toggle, hydraulic and portable models, to their working principles, advantages, and disadvantages.

More

How Does a Jaw Crusher Work? A Simple Guide - JXSC

2024年2月5日 A jaw crusher is a robust, essential and rugged crusher used primarily in mining and construction for the initial crushing of large rocks and ore. Positioned at the start of the crushing process, it uses compressive force

More

Jaw Crusher - an overview ScienceDirect Topics

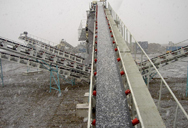

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a

More

What Are Jaw Crushers and How Do They Work?

How do jaw crushers work? Jaw crushers use compressive force to break down large materials into smaller, more manageable pieces. It has two crushing jaws (one is stationary while the other one is moving) that produces mechanical

More

Understanding Types of Jaw Crusher: A Comprehensive

Jaw crushers are absolutely vital in the mining world, helping us break down raw materials into something we can actually use. With all the different kinds of jaw crushers out there, you’re sure to find the perfect one for the job, whether

More

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards

More

Jaw Crusher Explained - saVRee

A jaw crusher uses compressive force for breaking ore pieces. Compressive force is applied by two jaws (dies), one of the crusher jaws is stationary (fixed jaw) whilst the other is moving (swing jaw). Material is fed into the top feed

More

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the

More

Differences Between the Metso C160 Metso C150

2024年2月12日 If you aren’t sure which jaw crusher model — the Metso C150 or C160 — is the best fit for your operation, the experts at Mellott can help. As an authorized distributor of Metso crushing equipment, our team has in-depth

More

Jaw Crusher: What Is It How Does It Work?

How To Use A Jaw Crusher? If you want to use a jaw crusher to crush rocks or other materials, there are a few key things that you should keep in mind. First, you will need to carefully select the jaw plates so that they can effectively

More

Eagle 2036 Jaw Crusher

Eagle Crusher's 2036 portable jaw crusher provides a lightweight yet high-strength construction, ideal for portable and skid-mounted applications. 1.800.25.Eagle (253.2453) DEALER LOCATOR

More

What Are Jaw Crushers and How Do They Work? - Oreflow

The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

More

Jaw Crusher Working Principle - 911Metallurgist

2021年5月6日 A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point. The motion is, however, a more complex one than the Dodge motion, being

More

Jonsson™ L160 Jaw Crusher - Tutt Bryant

L160 is powered by a large generator set or via main operation. Equipped with a Nordberg® C160 jaw crusher to efficiently process large quantities of hard materials, and powered by a 250 kW electric motor. For maximum capacity, the L160 has a feeder with grizzly where material that does not need to be crushed is pre-separated.

More

Jaw Crushers - McLanahan

McLanahan’s Universal Jaw Crusher produces more spec material at a lower cost per ton and ensures continuous crushing action with less abrasive wear ... We can ship you parts, send field service technicians to your site and answer any questions you have. Whatever you need, we are here for you. View Resources Contact Support Find A Dealer.

More

Metso C120 Jaw Crusher - Mellott

Nordberg® C120™ is a reliable jaw crusher engineered especially for quarrying and mining applications. Designed based on customer feedback and decades of experience at various customer sites, Nordberg® C120™ jaw crusher provides excellent productivity and low cost per ton, regardless of the end product.

More

Jaw Crushers - tesab

Unit 9, Gortrush Industrial Estate, Omagh, County Tyrone. Northern Ireland. BT78 5EJ

More

RC150V - RubbleCrusher.

The RubbleCrusher RC150V Trailer-Mounted Jaw Crusher is the perfect machine for all small to moderate crushing projects where construction and demolition “waste” materials can be recycled onsite, providing a great solution

More

Jaw Crushers Crushing Equipment Minyu

2023年8月7日 Minyu Jaw Crushers are configured for primary crushing of the hardest rock. Incoming material is crushed between the jaw crusher’s fixed die plate and movable die plate through advancing and retreating motions of the

More

Metso C150 Jaw Crusher - Mellott

The Metso Nordberg C150 jaw crusher is an effective crusher for demanding, large-scale mining and quarry operations. Large feed opening. Questions? Contact Us. Support. 855.554.1606. Sales. 855.424.6071. Skip to content.

More

VYKIN 8-JC Mobile Mini Tracked Jaw Crusher - VYKIN Crushers

Model: VYKIN 8-JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 0.26 – 0.52 gal/hr, 1.58 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic Control: Yes, tracks (rubber) Capacity: 2-8 TPH Crushing material: softer-to-medium hard rocks — such as concrete, limestone, pavers, demolition waste, tile,

More

Jaw Crusher: Range, Working Principle, Application - DSMAC

A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small enough to escape from the bottom

More

Jaw Crusher PE 600 x 900mm for Sale - SINO Plant

Standard jaw plate material Mn13 Wrist plate HT200 to protect the jaw plate excludes frame and belts, and should be fitted to a concrete base. Size of Feed Port: 900L x 600W Max Size: 480mm Discharge Port Size: 65 – 160mm Capacity: 70 – 190 t/hr Eccentric Shaft Speed: 250rpm Motor Power: 75kW / 380V []

More

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension.

More

Jaw Crusher for Primary Crushing Fote Machinery

PE/PEX jaw crusher is an earlier type with a simple structure. The PE type is a primary jaw crusher, and the PEX type is a secondary jaw crusher. It is the main crushing equipment in the small stone production lines. Maximum feed size: ≤1,200 mm Discharge particle size: 10 – 350 mm Capacity: 1 – 1,200 t/h 2. HD German type jaw crusher

More

The Most Practical Jaw Crusher Repair and Maintenance Manual

2023年2月15日 a template of jaw crusher checklist 2.Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important. It can minimize the friction generated during the operation, make the whole jaw crusher run

More

Jaw Crushers - Material Testing Expert

2023年11月23日 Pitman: Holds the movable jaw and moves it up and down. Toggle Plate: Acts as a safety mechanism, preventing damage to the crusher when uncrushable material is fed. Eccentric Shaft: Drives the movable jaw and imparts the crushing action. Materials Used. Manganese Steel: For jaw plates due to its durability and ability to withstand high impact.

More>> Next:Position Broyeur De Pierres De Carrière Analysismine