Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel. From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in

More

From Ore to Iron with Smelting and Direct Iron

2017年10月17日 Ironmaking is a critical step in producing high performance steel because high-quality raw materials reduce the time and energy to purify the iron to steel. On the other hand, newer smelting and direct iron reduction

More

Iron processing - Smelting, Refining, Alloying Britannica

The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention

More

Ironmaking Process - an overview ScienceDirect Topics

Ironmaking is to convert iron ore or other iron-bearing materials into a form that can be easily transformed into steel. This is done primarily in a BF with other auxiliary facilities to smelt the

More

Steelmaking - Wikipedia

Steelmaking is the process of producing steel from iron ore and/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur, and excess carbon (the most important impurity) are removed from the sourced iron, and

More

A critical review on metallurgical recovery of iron from iron ore ...

2024年4月1日 Iron ore tailings (IOTs) are by-products generated during the beneficiation process of iron mining, encompassing stages such as gravity separation, magnetic separation,

More

(PDF) i) Direct Reduced Iron: Production - ResearchGate

2016年3月30日 Processes that produce iron by reduction of iron ore (in solid state) below the melting point are generally classified as DR processes. Based on the types of reductant used, DR...

More

Forging Ahead: Ironmaking Innovations in the Steel

Ironmaking, the process of converting iron ore into molten iron, is a critical step in steel production. Over time, the steel industry has seen remarkable advancements in ironmaking technologies, driven by the need for increased

More

Iron Making: Exploring Traditional and Innovative Techniques for ...

Iron production is the process of extracting iron from iron ore through a series of chemical and physical processes. Iron is an important material used in many applications, including

More

Process of making iron from the ore. - Google Patents

It is then quite possible to modify the process by supplying oxid at such a rate that thedeposited' metal will be taken from the silicate of iron already in the furnace in part, if'not entirely, and perhaps with an acid silicate it .may be practically possible to so far modify the process that there shall be absolutely no solution of the iron ...

More

The manufacturing of iron from iron ore involves the process of ...

2023年6月7日 The production of iron from its ore involves an oxidation reduction reaction carried out in a blast furnace. Iron ore is usually a mixture of iron and vast quantities of impurities such as sand and clay referred to as gangue. The iron

More

How to Recover Iron from Magnetite: 4 Methods and

2023年4月7日 Magnetite is the main mineral in iron ore beneficiation, which has industrial value and is mined in large quantities. Here we will introduce the beneficiation method and process of magnetite ore in detail. What is

More

Iron Ore Mining – The process of iron ore mining - Atlam Group

The world’s reserves of iron ore are estimated to be around 170 billion tonnes, with the majority of these reserves located in Australia, Brazil, China, India, and Russia. These four countries account for about 85% of the world’s total iron ore reserves. How Is Iron Ore Used? Iron ore is used in a variety of different ways.

More

In the intricate world of steel production, misrolls at steel mills ...

In the intricate world of steel production, misrolls at steel mills represent a hidden danger that can have far-reaching consequences. These errors,...

More

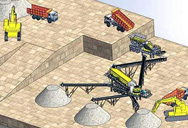

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

More

The Sintering Process of Iron Ore Fines – IspatGuru

2013年3月9日 The Sintering Process of Iron Ore Fines. satyendra; March 9, 2013; 9 Comments ; flux sinter, Iron ore fines, self fluxing sinter, sinter, sinter machines, Stright line machine. circular machine, super fluxed sinter,; The Sintering Process of Iron Ore Fines. Sintering plants are normally associated with the production of hot metal in blast furnaces in

More

The manufacturing of iron from iron ore involves the process of

The manufacturing of iron from iron ore involves the process of a) Oxidation b) Reduction c) Electrolysis d) Fractional distillation

More

Sponge iron making process PPT Free Download - SlideShare

2014年11月9日 The document discusses the inputs and process for manufacturing sponge iron in a rotary kiln. It describes the chemical and physical ... IRON ORE • Iron = 65-67 % • SiO2 + Al2O3 = 2-3 % • CaO + MgO = 0,5-1 % • Sulphur = 0,02 % max • Phosphorus = 0,04 % max Chemical Composition • Size = 5-18 mm • Shatter ...

More

Understanding the Steel Making Process: A Flow Diagram

2024年3月20日 The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram. It discusses the key ingredients involved in steel production, their roles, advantages and disadvantages of the workflow

More

Iron Ore Mining – The process of iron ore mining

The world’s reserves of iron ore are estimated to be around 170 billion tonnes, with the majority of these reserves located in Australia, Brazil, China, India, and Russia. These four countries account for about 85% of the world’s total iron

More

Iron (Fe) Ore Minerals, Occurrence » Geology Science

2023年5月7日 Description and properties of common iron ore minerals. Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted. Common iron ore minerals include:

More

How Iron and Steel Work - HowStuffWorks

Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores. The most primitive facility used to smelt iron is a bloomery. There, a blacksmith burns charcoal with iron ore and a good

More

Extraction of iron - IGCSE Chemistry Revision Notes - Save My

2024年9月24日 Carbon monoxide reduces the iron(III) oxide in the iron ore to form iron This will melt and collect at the bottom of the furnace, where it is tapped off. iron(III) oxide + carbon monoxide → iron + carbon dioxide. Limestone (calcium carbonate) is added to the furnace to remove impurities in the ore

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

More

Manufacturing Process From Ore To Stainless Steel: A Step-by

2023年3月13日 The process of extracting iron ore involves mining, where large-scale excavation is carried out to access the ore deposits deep within the earth. Once the iron ore is extracted, it undergoes a series of processing steps to remove impurities and prepare it

More

Evolution of Ironmaking Techniques From Ancient to Modern

As societies progressed, humans began to extract iron from terrestrial sources, marking the transition from the use of meteoric iron to smelting iron ore. One of the earliest known methods of iron smelting was the bloomery process. This ancient technique, dating as far back as 1200 BCE, involved heating iron ore in a furnace with charcoal.

More

23.3: Metallurgy of Iron and Steel - Chemistry LibreTexts

Originally, the iron was collected in pools called pigs, which is the origin of the name pig iron. Figure \(\PageIndex{1}\): A Blast Furnace for Converting Iron Oxides to Iron Metal. (a) The furnace is charged with alternating layers of iron ore (largely Fe 2 O 3) and a mixture of coke (C) and limestone (CaCO 3).

More

Exploring Steel Manufacturing: A Step-by-Step Insider Guide

2024年1月4日 Steel manufacturing is a complex process that transforms iron ore into steel, involving precise heating and mixing to create different grades for various applications. The journey includes primary methods like Basic Oxygen Steelmaking BOS and Electric Arc Furnace EAF, followed by secondary refining to meet specific quality standards.

More

Steel Manufacturing: Process, Types, and Standards - Thomasnet

2024年5月13日 The Steel Manufacturing Process. The steel production process is a multi-faceted journey that begins with extracting and processing iron ore, a primary raw material essential to steel making. Iron ore undergoes a series of refining steps to extract the iron content, culminating in the creation of molten iron.

More>> Next:Un Simple Machines De Concassage De Carrière à Vendre