Crushing and Screening Handbook - AusIMM

crushing process. The design of our certifi ed wear parts starts with CAD simulations of the crusher cavity, which is the heart of the crush-ing process. By computer based planning and continuous quality control of the casting we can guarantee premium material quality, which

More

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules th

More

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Crushers. Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary crushing operation, boulder size feeds from 20 to 100 in.

More

11.19.2 Crushed Stone Processing and Pulverized Mineral Processing

A variety of material, equipment, and operating factors can influence emissions from crushing. These factors include (1) stone type, (2) feed size and distribution, (3) moisture content, (4)

More

Understanding the Stone Crusher Manufacturing Process

The process of manufacturing stone crushers involves several steps, each designed to turn raw materials into finished products that meet specific industry needs. In this section, we’ll explore the fascinating world of manufacturing

More

Construction, Working and Maintenance of Crushers for Crushing

Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the intended end use. The goal of a crusher is to crush the

More

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 This article provides a comprehensive guide to primary, secondary, and tertiary crushing. We will delve into each stage of the crushing process, discussing the types of crushers used, their working principles,

More

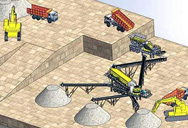

Crushing Plant Design and Layout Considerations - 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

More

Crusher manufacturing - Uğurmak Crushing and Screening Plants

2024年10月1日 Crusher manufacturing covers the production process of crusher machines that form the basis of stone crushing and screening facilities. These machines are important equipment used in construction, mining and other industrial applications and are also referred to as stone crushers. Crushing and screening plants are critical areas that play an important role

More

Artificial Sand Manufacturing Process - Eastman

2020年2月10日 There are mainly three steps of crushing, washing and screening in the artificial sand manufacturing process. The crusher machines of the crushing step may employ use jaw crusher, impact crusher, cone

More

crushing in cement manufacturing process

2023年11月8日 Crushing is an essential step in the cement manufacturing process, playing a crucial role in preparing the raw materials for further processing. The process of crushing raw materials such as limestone, clay, and iron ore involves reducing their size and preparing them for the next stages of production. In the...

More

Maharaja Stone Crusher

Our Manufacturing Process in Action. Manufacturing Solutions. ... At Maharaja Stone Crusher, we offer a variety of manufacturing services customized to your needs, from design to production. Our team of experts will work with you to ensure your project is

More

How Cement Is Made - Cement Manufacturing Process

Most of the machinery required by a cement manufacturing plant are huge and heavy - duty type. This is mainly due to the nature of the mineral inputs used in the production. Crushing plant for raw materials: jaw crusher, gyratory crusher, impact crusher, cone crusher etc.

More

Amazing Manufacturing Process of Jaw Crusher Machine

2023年11月19日 Amazing Manufacturing Process of Jaw Crusher Machine Hammer in Factory Production of Crusher Hammer#progress #manufacturing #amazingskills...

More

Chapter 4 Cement Manufacturing and Process Control

The early manufacturing process of cement was through wet process, in which slurry, made of ground raw material and water, used to feed the rotary kiln. ... Crusher Grinder Clay Raw Meal Kiln Grind Clinker Additive Cement Fig. 4.1 Flow sheet of cement manufacturing process 4 Cement Manufacturing andfiProcess Control. 63

More

Eagle Crusher Company - Manufacturing Express

2024年9月13日 Eagle Crusher manufactures impactors, jaw crushers and cone crushers for any application. These products are designed for the recycling industry to easily process concrete with the highest volume of rebar. Eagle Crusher was the first to bring concrete recycling to North America and in 1984, Eagle Crusher built the first US commercial recycling ...

More

Manufacturing process - Lafarge

The other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron ore. The high purity limestone is crushed in a lone in jaw crusher and then crushed more in a secondary crusher to reduce the size to

More

Cement Manufacturing Process - INFINITY FOR CEMENT EQUIPMENT

Cement Manufacturing Process . by TIZITA MOGES , SELAMU ABULE DEREJE ENDALAMAW . IF YOU NEED THIS GUIDE AND ALL OTHER USEFUL EXCEL SHEETS WHICH WILL MAKE YOU MASTER THE PRODUCTION , ... Crusher is a device that is designed to reduce large solid chunks of raw material into smaller chunks.

More

Automated process control system of Jaw crusher production

2021年12月1日 crusher production process as a solution for the real specified p roblems to get more productive . aggregate production. First a 3D model which mimic exactly the real crushing plant was built to .

More

Amazing Manufacturing Process of Jaw Crusher Machine

2023年11月19日 Amazing Manufacturing Process of Jaw Crusher Machine Hammer in Factory Production of Crusher Hammer#progress #manufacturing #amazingskills...

More

dap fertilizer production process # dap fertilizer

Tongda dap fertilizer production process could make your solid dap, map, sop, mkp and urea fertilizer into powder or granular dap fertilizer, which can. Skip to content ... crush the solid dap fertilizer. Thus, fertilizer crusher is

More

Crusher Manufacturing - Edim Mühendislik

Crusher manufacturing forms the backbone of raw material processing and material preparation processes in industrial facilities. At Edim Engineering, we produce various types of crushers, providing high-quality and durable solutions to meet our clients’ needs.

More

How Cement Is Made - Cement Manufacturing Process

This is mainly due to the nature of the mineral inputs used in the production. Crushing plant for raw materials: jaw crusher, gyratory crusher, impact crusher, cone crusher etc. Cement grinding mill: Grinding occurs at the beginning and the end of the cement making process. Grinding mill is the important machinery in cement production line.

More

Eagle Crusher Company - Manufacturing Express

2024年9月13日 Eagle Crusher manufactures impactors, jaw crushers and cone crushers for any application. These products are designed for the recycling industry to easily process concrete with the highest volume of rebar. Eagle Crusher was the first to bring concrete recycling to North America and in 1984, Eagle Crusher built the first US commercial recycling ...

More

manufacturing process flow chart-HXJQ Crusher Machine

Dec 12, 2018 Document the manufacturing process from start to finish to remain consistent and thorough during every step of the process. Include key details in the manufacturing industry, such as suppliers, raw materials, quality assurance, and packaging, to ensure that each product is manufactured with efficiency and accuracy.

More

Process Of Construction Waste Sand Making Plant

5 天之前 Industrial By-products: Some cement production processes yield by-products like fly ash or slag, which are recycled into sand with appropriate processing. Construction Waste Sand Making Plant Process It must undergo a series of processing steps to utilize cement waste.

More

Crusher Production Management System - Essae Digitronics

The software integrates all essential modules, including Machinery, Accounting, Warehouse, Production and Manufacturing, and Labour Management, into a single platform. This integration streamlines processes and enables real-time monitoring and control of all aspects of the crusher plant operation.

More

Artificial Sand Manufacturing Process - Eastman Rock Crusher

2020年2月10日 There are mainly three steps of crushing, washing and screening in the artificial sand manufacturing process. The crusher machines of the crushing step may employ use jaw crusher, impact crusher, cone crushing, hammer crusher, sand maker. The artificial sand size different, the crushing equipment is different.

More>> Next:Machines Crusher Vendre à Sri Lanka