Raw Mill – Raw Mill In Cement Plant AGICO Cement

Cement ball mill and cement vertical mill are two raw mills commonly used in cement plants. As the main cement equipment in the cement production line, the two cement raw mills have different characteristics.

More

Raw mill - Cement Plant

Vertica raw mill, also known as vertical roller mill, in the 1920s, the first vertical raw mill in cement plant is designed in German. It is widely used in cement, electric power, metallurgy,

More

Thermodynamic Performance Analysis of a Raw Mill System in a

2018年1月1日 In this chapter, energetic and exergetic analyses of a raw mill in a cement facility were performed for a better understanding of the system design dynamics. The exergy

More

Cement Plant: The Manufacturing Process 4 5 - World Cement

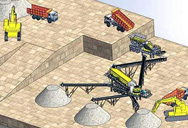

consumers The crushed limestone and aggregates such as sand, clay and ironstone are blended together in a raw mill to a particle size of 90 micrometres, producing “kiln feed”.

More

The Cement Plant Operations Handbook - International Cement

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide. Providing a

More

Cement Raw Materials Grinding Process (Raw Mill System

2022年3月3日 We will explain the cement raw materials that are ground in the Raw Mill system, and what types of equipment are used in the raw material milling process. Raw materials in

More

Raw Mill in Cement Plant Cement Manufacturing Raw

A raw mill with a superior fineness and well-controlled chemical composition using as advanced control system can improve the cement quality and define critical cement craft parameters. Amrit Cement uses the best of raw materials

More

Mercury emission characteristics and mechanism in the raw mill

2022年5月15日 Cement clinker production is the top emitter of atmospheric mercury in China and the emissions from raw mill systems account for about 85% of all emissions. However, the mercury emission characteristics and mechanisms as a function of time during an operation cycle are still unclear.

More

Raw Mill Moisture Content Management: A

5.1. Case Study: Rotary Dryer Implementation in a Middle Eastern Cement Plant. A cement plant in the Middle East faced issues with high moisture content in its raw materials, leading to frequent mill stoppages and reduced output. By

More

Raw Mill in Cement Plant Cement Manufacturing

Learn about the raw mill in cement plants and the basic raw materials used in cement manufacturing. Discover our efficient cement manufacturing process. Contact us for ... Limestone from mines are brought to plant site and stored in

More

What does a Raw Mill do in Cement Plant? - ball mills supplier

We hope this guide has helped you understand what a raw mill is, how it works, and its benefits. If you have any further questions, feel free to ask us in the comments section below. FAQs What raw materials are used in a raw mill in a cement plant? The raw materials used in a raw mill in a cement plant include limestone, clay, shale, and iron ore.

More

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

More

The 6 Main Process Fans in Cement factory

Raw mill fans: Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. Induced draft fans: Induced draft fans ...

More

PROCESS TRAINING for operators of Vertical RAW Mills

For drying the wet raw material it is necessary that prior to the mill start up the grinding plant is.heated for some time.Otherwise the cold grinding plant would take away too much heat from the drying process and the finish product would not be dry – handling problems in the meal transport and silo extraction would follow.

More

A predictive maintenance model for an industrial fan in a cement plant

2020年9月2日 The material efficiency values for a raw mill, pyro-processing tower, rotary kiln, ... Through the application of a fully integrated cement plant located in Northern Nigeria as case study; ...

More

Coal Mill In Cement Plant

Air-swept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coal.It is the important auxiliary equipment of pulverized coal furnace. The air-swept coal mill runs reliably, can work continuously, also has a large production capacity and less energy

More

Material Mix Control in Cement Plant Automation

Smidth of Denmark, a pioneer in cement plant auto- mation, on a 2500 tons-per-day (tpd) dry process cement plant situated at Jayanthipuram, Andhra Pradesh, India ... testing of a raw material mix proportion control for a cement plant raw mill. A systematic design method is given for raw mix proportion control which accounts for the dead ...

More

Cement Conveyor Belt Conveyor In Cement Plant AGICO

Cement conveyor refers to a belt conveyor in cement plant, which is necessary accessory equipment in the cement production line.. A belt conveyor is a kind of material handling equipment with strong adaptability, applied for conveying bulk density less than 1.67t / m³, it is mostly used for powder, granular, small lump materials, and bagged materials, such as sand,

More

Raw mill operation in cement plant (Siemens PCS7 OS panel)

2018年9月23日 This is the practical demonstration of how a raw mill operator puts the raw mill of a cement mill in operation by using Siemens PCS7 DCS OS panel. This raw m...

More

Coal Mill in Cement Plant

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 0.5% ~

More

Powerpoint presentation on CEMENT {PPT} - SlideShare

2017年3月8日 4. Characteristics Of Cement • Color should be grey with greenish shade • It feels smooth when touched • It feel cool and warm when hand inserted in bag of Cement. • It should free from hard lumps • When immersed

More

Cement Roller Press - Roller Press In Cement Plant Roller Press ...

In a cement plant, a cement roller press is a kind of important cement equipment used for clinker grinding. It is usually combined with a cement ball mill to form a high-efficiency cement grinding system because the practice shows that the grinding process with a small grinding ratio and step-by-step completion is more energy-saving than that with a large one-time completion.

More

Material Mix Control in Cement Plant Automation

Smidth of Denmark, a pioneer in cement plant auto- mation, on a 2500 tons-per-day (tpd) dry process cement plant situated at Jayanthipuram, Andhra Pradesh, India ... testing of a raw material mix proportion control for a cement plant raw mill. A systematic design method is given for raw mix proportion control which accounts for the dead ...

More

How Does a Raw Mill Work in a Cement Industry

2024年2月23日 The operation of the cement raw mill is a critical step in cement production. By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process. Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality

More

Cement Milll Separator Cyclone Air Separator in Cement Plant

Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants.The function of the separator is to separate the fine-sized particles from the coarse-sized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s grinding efficiency.

More

Optimizing Electrical Energy Consumption In Cement Process

Selection of appropriate energy efficient equipment for various unit operations in a cement plant like stacker - reclaimer systems for pre-blending, ... Cement Mill - 33% Raw Mill - 24% Kiln - 23% Losses and crane etc - 10% Coal Mill - 7% Quarry Crusher Stock Pile -

More

What does a Raw Mill do in Cement Plant? - ball mills supplier

We hope this guide has helped you understand what a raw mill is, how it works, and its benefits. If you have any further questions, feel free to ask us in the comments section below. FAQs What raw materials are used in a raw mill in a cement plant? The raw materials used in a raw mill in a cement plant include limestone, clay, shale, and iron ore.

More

Atif Mehmood - VRM Operator Raw Mill and Coal Mill - Pioneer Cement ...

VRM Operator Raw Mill Coal Mill at Pioneer Cement Pakistan. 106 followers 103 connections See your mutual connections. View mutual connections with Atif Sign in Welcome back ...

More>> Next:Broyeur Concasseur Machines