Impact Crusher Maintenance Guide Your Daily

Check Impact Crusher. Before opening the crusher box, activate the RM Release System manually to loosen packed dirt and ensure the impact wall swings freely. Check for wear and damage and replace worn parts if needed.

More

IMPACT CRUSHER - Qiming Machinery

Execute maintenance or repair work only when crushing plant stands still and electric plant is switched off. Lock main switch against erroneous or unauthorised starting of the plant. Check

More

Inspection Checklist (Crusher 3) PDF - Scribd

The document is an inspection checklist for Crusher-3 containing 12 items to check including a belt conveyor, primary impact crusher, secondary impact

More

Maintenance Manual

This Maintenance Manual provides detailed information on the proper care and maintenance of MSW Stone Crusher equipment, including Jaw Crushers, Cone Crushers, Impact

More

Impact Crusher working principle parts and maintenance

By following proper maintenance procedures and addressing any issues promptly, you can minimize downtime and maximize productivity with your impact crusher. Remember to

More

4 Types of Stone Crushers' Maintenance and Efficient

2024年10月14日 There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how

More

MEKA CRUSHING SCREENING AND CONCRETE BATCHING

Our MPI crushers are high capacity crushers that are designed to reliably produce cubical product shapes. The final shape delivered aims to meet the exacting specifications for

More

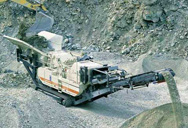

Mobile Crusher Maintenance and Operation Guide

2024年3月18日 In this guide, we will explore the key aspects of mobile crusher maintenance and operations, providing valuable insights to maximize productivity, minimize downtime, and

More

Maintenance Guidelines for Impact Crusher - huashengming

2024年9月5日 Establish a Maintenance Record: Create detailed maintenance records for each piece of equipment, including repair dates, repair details, and information on replaced parts.

More

Mobile Crusher Maintenance and Operation Guide

2024年3月18日 Summary:This comprehensive guide covers essential maintenance and operation procedures to maximize productivity and uptime of mobile crusher. Mobile crushers play a crucial role in various industries by efficiently crushing and processing materials on-site. To ensure their optimal performance and longevity, it is essential to follow proper maintenance

More

Crusher-Safety-Checklist HVI APP - Heavy Vehicle

2024年4月24日 Download the checklist now. Top 10 FAQs on the Crusher Safety Checklist. 1. Q: How often should I conduct safety training for crusher operators and maintenance staff? A: It is recommended to provide

More

Inspection Checklist (Crusher 3) PDF - Scribd

Inspection Checklist (Crusher 3) - Free download as Excel Spreadsheet (.xls / .xlsx), PDF File (.pdf), Text File (.txt) or read online for free. The document is an inspection checklist for Crusher-3 containing 12 items to check including a

More

crusher daily checklist - KOOKS

Pre Start Safety Checklist For Crushers - ssaconsultantsin. impact crusher daily - arpainternationalin Aggregate crusher Daily Maintenance checklist- impact crusher daily,Stone Crusher Machine From China ZenithThis page is .

More

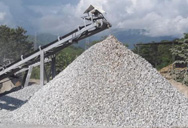

(PDF) Design of Impact stone crusher machine - ResearchGate

2019年5月31日 Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to ...

More

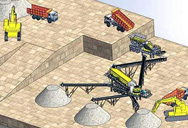

Primary Crusher vs. Secondary Crusher: Understanding Their

2023年2月28日 Impact Crusher Menu Toggle. LF Large-Diameter Impact Crusher; CS5X Impact Crusher; PF Impact Crusher; PFW Impact Crusher; Cone Crusher Menu Toggle. ... and the maintenance and safety procedures required. Additionally, we will compare primary and secondary crushers and provide real-world examples of their applications.

More

Impact crusher application and spare parts introduction

2024年3月4日 Impact crushers have gained widespread recognition in the construction and mining industries for their ability to efficiently crush a variety of materials. With their robust design and versatile applications, impact crushers play a crucial role in various stages of material processing. Impact Crusher Applications:

More

What is an impact crusher? - AGICO

2023年3月11日 An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series of hammers. As the rotor spins, the hammers strike the material, causing it to break into smaller pieces.

More

Maintenance and Repair of Stone Crusher Machines

2023年2月22日 Stone crusher machines are widely used in the construction and mining industries to break down large stones into smaller pieces. To ensure that these machines operate efficiently and remain in good condition, regular maintenance and repair are necessary. In this article, we provide a comprehensive guide to the maintenance and repair of stone crusher

More

Impact crusher parts - Metso

The impact crusher parts range consists of spare parts and wear parts. ... Do you know what parts you need for your next maintenance to ensure high crusher uptime? All the parts for your 250, 1,000 and 2,000 hour preventive maintenance come in convenient, cost-efficient parts kits.

More

5 Maintenance Ways for Plastic Crusher

2023年10月17日 Environmental impact: The use of plastic crusher machines is essential in reducing plastic waste and promoting environmental sustainability. The shredded plastic material can be recycled or reused in various applications, reducing the need for new plastic production and reducing waste.

More

Rock crusher inspection report, checklist crusher

Checklist for crusher inspections. When inspecting and comparing impact crushers and jaw crushers, there are some specific points to consider for each type of crusher. Here’s a checklist highlighting the key differences for both

More

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the

More

Impact Crusher Working Principle - 911Metallurgist

2015年6月23日 Test Procedures for the Characterization of Crusher Performance. The Bond Impact Work Index method has been an industry standard for the determination of crusher power requirements but was originally developed to ensure, that sufficient power was connected to primary gyratory crushers.

More

What Are the Differences Between The 7 Types of Crushers?

2024年7月15日 Purchase and Maintenance. In the beginning, you spend more money on cone crusher than that of impact crusher. But cone crusher does not need maintenance so much because it has hydraulic system to protect the whole machine and has a longer life span. The wear parts of impact crusher are hammer and aprons.

More

Impact Crusher - an overview ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to fully utilize the high-speed impact energy of entire rotor.

More

PF Impact Crusher

5. A new type rotor to increase the impact force; 6. High productivity, low energy consumption, high overall efficiency. 7. Simple structure, easy maintenance and reliable. Application of PF Impact Crusher The impact crusher is widely used

More

What are the advantages and disadvantages of impact crushers?

2023年9月26日 In today’s industrial production, the application of crusher equipment has become more and more widespread. Among them, the impact crusher is widely used in many industries such as mining, metallurgy, chemical industry, and building materials due to its unique working principle and excellent performance. However, any equipment has its advantages and

More

Impact Crusher vs. Jaw Crusher

2020年11月20日 In contrast, an impact crusher produces smaller materials that result in sizes of half a centimeter to 20 centimeters. Impact crushers can also bring out finer and more consistent shapes than a jaw crusher. It also produces more dust in the process. Depending on your project you may want to combine the use of a jaw crusher and an impact crusher.

More

Application And Maintenance Of Impact Crusher

Advantages Of Impact Crusher: 1. it is effective for impact crusher processing wet moisture material and prevents materials from blocking. When the moisture content of the material is too large, the feed chute and impact plate can be equipped with a heating device to prevent the adhesion of the material, and there is no need to provide the bottom screen plate to avoid

More>> Next:Algérie Petit Concasseur De Roches Phosphatées à Vendre