Transforming iron ore processing - ScienceDirect

2023年8月1日 Reverse cationic flotation, which involves the flotation of the gangue mineral, is the most widely used method of fine iron ore beneficiation (Filippov et al., 2014).

More

Fine Dry Grinding of Iron Ore for Pelletizing - 911Metallurgist

2019年6月20日 Most dry iron ore grinding installations utilizing the standard type rod or ball mill are grinding high-grade natural ores that do not require beneficiation. Most of these ores

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

2018年7月11日 The iron ore pellet holds a pivotal role in the ironmaking process, enabling the utilization of high-grade ore and the upgrading of low-grade deposits [1]. This process involves several...

More

Iron ore - Wikipedia

Lower-grade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, high-quality fine ore powders, are known as fines. Magnetite is magnetic, and hence easily separated from the gangue minerals and capable of prod

More

Fine Grinding as Enabling Technology – The IsaMill

Stirred milling was developed for fine grained ores that required an economic grind to sub 10 micron sizes. The first examples were lead zinc deposits – McArthur River, George Fisher and

More

Study of Iron Ore Mixtures Behavior in the Grinding Pelletizing

2016年11月14日 Three iron ore mixtures with different grindability index (low, medium, and high) were used in order to verify the influence in the operational parameters such as

More

Ore Grinding - SpringerLink

2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size. In the mineral processing industry, ore grinding is the particle size preparation before the

More

Beneficiation of Low-Grade Hematite Iron Ore Fines by

2024年2月8日 Present investigation includes the magnetizing roasting of low-grade iron ore fines followed by grinding and beneficiation using magnetic separation. The hematite iron ore used in the investigation contains 53.17% T

More

Agglomeration of Iron Ores - SpringerLink

2023年6月11日 Powdery iron ore includes the concentrate and natural rich ore produced by fine grinding separation. Iron ore powder agglomeration is the basis for blast furnace ironmaking

More

Processing of Magnetite Iron Ores - Comparing Grinding Options

Although the majority of current steel production is supported by iron ore sourced from high-grade haematite deposits, the long-term growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developed._x000D_ There is a rich and long history of magnetite ore processing in Western countries, including

More

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Grinding and beneficiation are essential stages in iron ore processing that involve reducing the ore size and removing impurities to enhance the concentration of iron-bearing minerals. These processes aim to improve

More

Comminution and classification technologies of iron ore

2022年1月1日 Conversely, fine-grained magnetite ores require fine grinding, often to below 30 μm, to liberate the magnetite from the silica matrix, incurring greater costs and energy consumption. ... from final stages of crushing through to grinding applications. In iron ore operations they are mostly used for pretreating pellet feed in pellet ...

More

Advances in screening technology in the mining sector

Screening is mainly used in the mining sector in primary and secondary crushing systems (Fig. 3), coarse screening (scalping) in the pre-heap leaching process, fine screening and fine-grain elutriation in various process stages, enrichment of valuable materials, e.g. of the iron content in iron ore, grinding and screening circuits (open and closed) and screens in DMS circuits

More

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy

More

Development of a Novel Grinding Process to Iron Ore Pelletizing

2020年3月28日 The grinding product t10 is negatively correlated with the feed sizes of ore when the grinding force is applied to the ore. At the same time, it has a simple positive linear relationship with the ...

More

Beneficiation of micro-fine magnetic minerals from reductive iron ore ...

2017年10月31日 The results indicated that the iron phase in reductive iron ores was predominantly metallic iron (below 20 μm). By applying ultrafine grinding-magnetic flocculation separation (MFS) to the raw ore (29.85% Fe), a concentrate assaying 74.12% Fe with 81.45% iron recovery was obtained.

More

Potential of High-Pressure Grinding Roll (HPGR) for Size

2022年3月16日 2.1 Experimental Design. The experimental planning with selected key factor like operating gap (X 1), applied load (X 2) and roll speed (X 3) was designed by CCD method to obtain the optimum conditions for grinding the BHQ iron ore in HPGR.A full second-order polynomial model was obtained by regression analysis for three factors by using the Design

More

HPGR effect on the particle size and shape of iron ore pellet feed ...

2017年2月1日 HPGR effect on the particle size and shape of iron ore pellet feed using response surface methodology. ... 106 µm after fine grinding. Magnetic and gravity cir-cuits reduce the fines fraction, ...

More

Physicochemical Problems of Mineral Processing Investigation

2017年3月20日 An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studied.

More

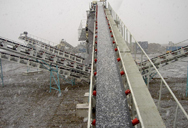

Fine Ore Storage Bin and Stock Pile - 911Metallurgist

2015年7月27日 Let’s begin with fine ore storage bin or stockpile, get it out of the way and then proceed to grinding.You would think that there isn’t that much to learn about when talking of fine ore storage, after all, all that this area is really for is to

More

Grinding Mill for Iron Ore Fines: Optimizing Mineral Processing ...

The grinding mill for iron ore fines is designed to handle the rigorous demands of mineral processing. It is equipped with advanced features that enhance its performance and efficiency. The mill’s robust construction and innovative design make it capable of grinding a wide range of materials, including iron ore fines.

More

Reducing Grinding Energy and Cost - Magnetite Iron Ore

Many banded iron formation deposits are very fine grained often ... Various magnetite ore grinding flowsheets have been implemented in the past, including: 71

More

Utilization of Iron Ore Tailings as Fine Aggregates in Concrete

2023年7月10日 For iron ore and concrete producers, using iron ore tailings as fine aggregate to produce concrete is an effective method of recovering iron ore tailings. Iron tailings can be made into iron tailing sand, which is mixed with conventional aggregates such as artificial sand to produce concrete that meets demand, such as C50 concrete.

More

Low grade Iron Ore Beneficiation and the Process of Jigging

2018年9月25日 In case of iron ores associated with the poor liberation, the ore requires fine grinding to obtain adequate degree of liberation of the desired iron mineral and the gangue constituents. The choice of the beneficiation treatment depends on the nature of the gangue present and its association with the ore structure.

More

Effect of different mills on the fine grinding characteristics and ...

2024年9月1日 Therefore, the development of an efficient fine- grinding mill is crucial owing to the extremely fine dissemination size of refractory gold ores. Fine grinding is a milling method of crushing materials to less than −0.1 + 0.01 mm by using grinding, impacting, shearing and other forces within the mill (Kumar et al., 2023).

More

Ultra Fine Grinding Mill - Ultra Fine Powder Grinder AGICO

What Is Ultra Fine Grinding Mill. The ultrafine powder grinding system is a new product independently developed by our company, mainly used to grind and classify various non-metallic ores in cement plants, such as the grinding of limestone powder, deep processing of pulverized coal, etc.This system is composed of an elevator, airlock device, superfine vertical mill (ultra

More

Liaoning A Processing Plant Iron Ore Column Mill Ultrafine Grinding

2023年11月16日 A plant in the north of the use of column mill ultra-fine crushing process, the ore crushed to -5mm for dry magnetic separation of coarse tailing, discard 50% of the tailings into the ball mill, so that the ball mill to increase production by more than 40%, and the entire crushing system to increase production to 280%, the entire system to reduce the cost of production of

More

Enhanced iron extraction from high-phosphorus waste limonite ore

2023年10月20日 Iron ore is an important metal resource for industrial production and is widely used in the steel industry for ... respectively. According to the previous studies, when the traditional multi-stage fine grinding-magnetic separation is used to treat the high-phosphorus limonite ore, the Fe grade of concentrate is just less than 50% ...

More

(PDF) Physical and Morphological Characteristics of Iron Ore

2011年9月14日 The two optimization measures including "fine grinding high chromium vanadium-titanium magnetite" and "replacement of the practical production iron ore with cheap finer Oukong powder (imported ...

More>> Next:Pierre Charbon Ligne De Concassage