Jaw Crusher - ScienceDirect

2016年1月1日 Iron ore was crushed in a jaw crusher. The average sizes of the feed ( F 80 ) and product ( P 80 ) were 50 and 10 mm, respectively. The energy consumed during crushing was

More

Roll Crusher - an overview ScienceDirect Topics

Roll Crushers. In Mineral Processing Design and Operations (Second Edition), 2016. 6.1 Introduction. Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which rotate a single roll against a fixed breaker plate. Mineral or rock particles placed between the rolls are nipped and

More

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 The machinery’s high-impact movement typically relates to a high production rate in a primary crusher. For instance, a standard jaw crusher diagram might show a feed rate of 500 tons per hour, translating to

More

SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

More

Department of Fuel, Minerals and Metallurgical Engineering

1. Laboratory models of double roll crusher, jaw crusher, and vertical rotary crusher. 2. Two samples of quartz/ iron ore/ limestone and four samples of coal, each weighing about 4 kg. All the six samples should be entirely of –1½” + ¾” size and

More

Jaw Crusher VS Roller Crusher - Baichy

2023年6月29日 Both jaw crusher and roll crusher are simple structure and crush hard material by extrusion force.Jaw crushers are mainly used for coarse crushing and medium crushing processes, ... Gold ore processing plant; Iron ore beneficiation process; Cooper ore processing plant; Customer Case.

More

Mining Technologies Eccentric roll crushers ERC

Jaw gyratory crusher Jaw crusher ERC ® eccentric roll crusher Discrete Element Method (DEM) Simulation Housing Integrated static grizzly Roll with eccentric shaft Hood Jaw Hydraulic gap setting system V-belt drive Hydraulic power unit Base frame Flywheel with movable safety cover Fines are screened out by means of an integrated grizzly

More

Ore Crusher - PE Series Jaw Type Ore Crusher - AIMIX

Introduction of Iron Ore Crusher Machine: ... Processing capacity(t/h): 16-60 Rotation speed of eccentric shaft(r/min):275 Mixing power(kw): 30 Total weight(T): 7 ... A fine jaw crusher is generally used in small iron ore factories. It has a simple structure and convenient maintenance.

More

Comminution and classification technologies of iron ore

2022年1月1日 Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BF-BOF) route or through the electrical arc furnace (EAF) route. The majority of world crude steel is made from the BF-BOF route.

More

Estimate Jaw Crusher Capacity - 911Metallurgist

2016年2月18日 From Allis-Chalmers’ Superior Primary and Secondary Crushers. ° Actual required depends on stone hardness, reduction ratio, and so on. If a 60-in. gyratory crusher is to process material from a quarry where a shovel loads the raw material, the shovel would probably have to have a dipper capacity of at least 5 cu yd to be compatible.

More

Roll Mill Crasher Machine For Iron Ore Crusher Mills, Cone Crusher

roll crusher for iron ore. SAM is a professional manufacturer and exporter of mining equipment, such as: crushing plant, mobile crushers, grinding mill machine, feeding conveyor, screening

More

Understanding Types of Jaw Crusher: A

Type of Jaw Crusher Best Suited for Ores Why Suitable; Single Toggle: All types, gold, copper, large quartz rocks: Efficient crushing of large-sized hard ores: Double Toggle: Hard and abrasive, iron ore, chromite, diamond-bearing

More

roll jaw crusher iron ore processing – stone cruxder

When it comes to crushing and processing iron ore, you need strong equipment that can handle tough materials. That’s where the roll jaw crusher steps in! This powerful machine combines a jaw crusher with a roll crusher, giving you a high-capacity solution for

More

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a

More

Roll Mill Crasher Machine For Iron Ore Crusher Mills, Cone Crusher

roll crusher for iron ore. SAM is a professional manufacturer and exporter of mining equipment, such as: crushing plant, mobile crushers, grinding mill machine, feeding conveyor, screening

More

What Are Jaw Crushers and How Do They Work? - Oreflow

The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

More

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

More

Ore Crusher - PE Series Jaw Type Ore Crusher - AIMIX

Introduction of Iron Ore Crusher Machine: ... Processing capacity(t/h): 16-60 Rotation speed of eccentric shaft(r/min):275 Mixing power(kw): 30 Total weight(T): 7 ... A fine jaw crusher is generally used in small iron ore factories. It has a simple structure and convenient maintenance.

More

Working Principle and Production Process of Iron Ore Jaw Crusher

2024年7月30日 Iron ore is the core raw material for steel production, and its processing is crucial to the sustainable development of the steel industry. In the processing of iron ore, crushing is the first step, which is directly related to the efficiency of subsequent processes and product quality. Among them, jaw crusher, as a commonly used crushing equipment, plays an

More

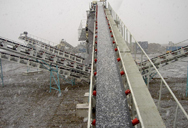

Process flow of Iron Ore Crushing Production Line

2022年1月19日 Huazn can produce ore crushing production line equipment and provide you with technical support. The ore crushing plant equipment usually consists of vibrating feeder, jaw crusher, hydraulic cone crusher, vibrating screen, belt conveyor and other equipment; suitable for Processing of non-ferrous metal minerals such as iron ore and gold ore; the designed

More

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

More>> Next:Configuration De Carriere De Calcaire