Crushing and Screening Handbook - AusIMM

Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process

More

An eccentric solution to the primary crushing concept - Quarry

2019年4月1日 A rotating eccentric shaft, axially guided by two sets of roller bearings mounted in the crusher housing, generates an oscillating movement in the freely rotatable, horizontally

More

Understanding the Different Types of Crushers - Agg-Net

2018年9月10日 Selecting an appropriate crusher, or indeed any piece of processing equipment, is important in every quarry operation. Understanding what each crusher type is used for and

More

Selecting the right type of crushing equipment - Quarry

2016年4月7日 A pit-portable primary crusher can be an economically sound solution in cases where the producer is crushing at the quarry face. In modern plants, it is cost

More

A review on the utilisation of quarry and ornamental stone

2016年1月15日 The high volume utilisation of the quarry dust and ornamental stone sludge can lead in a higher water demand. For this reason, superplasticizers have been added in the

More

Types of Rock Crushers Quarry Crushing Equipment Kemper

The number of crusher types in terms of style and configuration can be more challenging to quantify, as there are lots of ways to customize rock crushers. However, you’ll find four basic

More

Selecting the right crusher for your operations - Quarry

2020年3月19日 Components such as the crusher’s engine, hopper and wear liners are just as important in ensuring the best fit and keeping maintenance to a minimum. A powerful, well

More

Modelling of Crushing Operations in the Aggregates Industry

The project aimed to show whether there were functional relationships between the input data in the primary crushing phase (gap size (mm), feed size distribution, throughput (t/hr) and ore

More

What Is Quarry Crusher - On-site Processing Stone, Rock, Granite

Quarry crusher is a piece of equipment that break down natural stone or other solid materials, such as limestone, granite, cobblestone, quartz, and basalt, into sand, aggregates or gravel

More

QUARRY PRODUCTIVITY THREE STEPS TO VALUE - Sandvik Mining

When a quarry wants to optimize, it’s easy to concentrate on obvious value-creating events, such as crushing chamber performance. But these only account for about 5% of the entire quarry

More

What Is Quarry Crusher - On-site Processing Stone, Rock, Granite

150tph Quarry Crushing Line To Process Quartz. Applications: Used to crush quartz from different origins and then to produce quartz sand as raw material for glass and ceramics Raw materials used:up to 400mm Finished product demand:medium and fine sand between 0-3mm Yield demands:100TPH Crushing capacity:150TPH Configuration: APG-3895W (vibrating

More

UTILISATION OF AS GENERATED QUARRY DUST AS A FINE

generated’ (or rather ‘as supplied’) quarry dust. Quarry dust is a by-product formed particularly when metal is produced from rubble in metal crushers. There are two types of crushers in use of which the crushing mechanism differs. They are namely the jaw crusher and the cone crusher. With the jaw crusher, trubbles are

More

A review on the utilisation of quarry and ornamental stone

A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector Michael Galetakis⇑, Athanasia Soultana School of Mineral Resources Engineering, Technical University of Crete, Chania, Greece highlights Quarry and ornamental stone dust constitute a severe environmental problem.

More

Apa itu Quarry Crusher - Pengolahan Batu, Batuan, Granit di

Quarry crusher adalah peralatan yang memecah batu alam atau bahan padat lainnya, seperti batu kapur, granit, batu bulat, kuarsa, dan basal, menjadi pasir, agregat atau kerikil yang dapat digunakan untuk berbagai aplikasi konstruksi, seperti: produksi beton, aspal, landasan jalan, dan bahan bangunan lainnya.

More

KIS Bins – KIS – Quarry Services

KIS Bins are transportable by truck and used where dump trucks or loaders are the preferred option to transport raw feed to crushing/process plant.KIS offer various size and configurations of bins to suit the customers requirements.These bins aid plant production and contribute to a safe working environment. KIS Bins are all engineered to meet the safety requirements of the

More

(PDF) Sustainable Utilisation of Quarry Dust Waste in Concrete ...

2020年12月30日 PDF Each year, a large amount of quarry dust (QD) waste is disposed into landfills. This waste material was obtained as a by-product during the... Find, read and cite all the research you need ...

More

PT Best Crusher, Stone Crusher, Loading Conveyor, Best Quarry

It all began with a dream of becoming the BEST in providing best quality crusher machines and their parts since last two decades. PT Best Crusher Sentralindojaya import, manufacture as well as design crushing plants in Indonesia.. Satisfaction of our customers encouraged us to designing the best quarry plant.

More

Three reasons for oversized rocks in the primary crusher feed

2018年4月5日 The primary crusher is a vital part of the extractive process, taking the run of quarry aggregate and reducing it to a size that can be processed by the downstream operations. However, extractive operations frequently have issues related to the primary crusher: low throughput, low utilisation and high wear rate of liners.

More

utilisation du sable concassé selon lcpc Mining Quarry Plant

2013年3月26日 50% de concassé composition toujours selon dIn 1045 au sollicité pour ses roches massives pour faire du sable concassé et Utilisation de sable concassé 0

More

How to Choose the Right Crusher for Your Quarry

If your operation requires moving the crusher frequently, a mobile quarry crusher may be the best choice. On the other hand, if your quarry has a fixed location, stationary quarry crushers will go a long way. Operating and Maintenance Costs. Consider the energy consumption, wear parts replacement frequency, and overall maintenance requirements ...

More

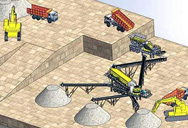

Enhanced plant design for aggregate processing

2012年5月1日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, pre-existing factors

More

Utilization of Quarry Dust to Improve the

2005年7月1日 Quarries and aggregate crushers are basic requisites for construction industry and quarry dust is a byproduct of rubble crusher units. Geotechnical and mineralogical characterization of quarry ...

More

Portable Crusher Plant for Stone Quarry in Nigeria

To meet the diverse needs of Nigeria's quarry industry, portable crusher manufacturers have developed a wide range of technological solutions that cater to the specific requirements of quarry operators. These crusher systems are typically classified based on their crushing mechanism, size, and mobility, each with its own set of features and ...

More

A review on the utilisation of quarry and ornamental stone

2016年1月15日 Several researchers have reported the possibility of exploiting the quarry waste, e.g., quarry dust as a suitable fine aggregate replacement [163, 164], limestone slurry [165], and chromite wastes ...

More

Maximising cone crusher performance - Quarry

2018年4月5日 With complete application data in hand, Schultz said it was important for operations to work closely with their crusher supplier to select the right crusher. The key considerations are: Crushing speed. Chamber design. Liner configurations. Crusher settings. “There are myriad choices of machine configurations,” Schultz said.

More

Tips for maintaining efficiency in crushing circuits - Quarry

2019年4月1日 It is important to match the CSS of the crusher to the top size of the product to be produced. If the circuit is being closed at 25mm (1”) to produce a 25mm minus product, the crusher should be set at, near or slightly below 25mm. {{image3-a:l-w:640}} Impact crushers. An impact crusher uses mass and velocity to break down feed material.

More

Lean Method to Identify Improvements for Operation Control at Quarry

2013年8月11日 Quarry Site Case Study 2 – Feeding Crusher The second case study observed the process seen in Figure 1, but excluding the moving activity since the site did not have a second buffer for the crusher.

More

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

More

Jaw Crusher Liners Foreman Equipment

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers Cookie Settings Office - Toll Free: 888-852-9021 44109 Yale Road West, Chilliwack, B.C. V2R 3Z9

More

Crusher Mining and Quarry Equipment For Sale in Australia

Find Crusher Mining and Quarry Equipment for sale in Australia - new used Crusher Mining and Quarry Equipment from KINGLINK, METSO, POWERSCREEN, MCCLOSKEY more on MachineryTrader.au

More>> Next:Equipamemtos De Beneficiamento De Ultima Geração