Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation parameters

More

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static

More

Reduction of Iron Ore Pellets, Sinter, and Lump Ore

2020年3月23日 The reduction of iron oxides occurs step wise from hematite to magnetite, magnetite to wüstite, and wüstite to metallic iron. Reduction occurs with CO and H 2 as shown here. [1] From hematite to magnetite (around 500

More

Estimating the lump to fines composition split in iron ore production

Iron ore is mined, crushed and separated into lump and fines components, which are sold as separate products. Quality (and therefore value) depends upon the shipped composition of

More

Study on Mechanical Properties and Reduction Behavior of

2023年8月23日 Fines iron ore oxides are generated during mechanized mining as well as comminution, beneficiation, transportation, and agglomeration processes. These iron ore fines

More

Impact of quality of iron ore lumps on sustainability of mining ...

2015年1月1日 Improving the quality of lump ore, through a simple yet innovative mineral processing, can maximize recovery of reserves, decrease waste generation, and increase the

More

Relating Iron Ore Lump and Fines Grade Split to Ore Type

2005年1月1日 When iron ore is crushed and split into lump and fines components, there are systematic differences between the lump and fines grades. Generally the lump product is

More

Relating Iron Ore Lump and Fines Grade Split to Ore Type - AusIMM

When iron ore is crushed and split into lump and fines components, there are systematic differences between the lump and fines grades. Generally the lump product is richer in iron

More

Estimating The Lump To Fines Composition Split In Iron Ore

Iron ore is mined, crushed and separated into lump and fines components, which are sold as separate products. Quality (and therefore value) depends upon the shipped composition of

More

NMDC hikes prices of iron ore lumps and fines by Rs

2022年3月8日 While lump is high-grade iron ore having Fe (iron) content above 65 per cent, fine is inferior grade ore which needs beneficiation. The revised prices are effective from March 8, 2022 and exclude royalty, District

More

Study of Mineralogy and Metallurgical Properties of

2022年10月25日 The purpose of this study was to conduct experiments comprising the high-temperature reduction treatment of commercially produced iron ore fines and lumps aimed at increasing the use value of the ore.

More

Beneficiation of Indian Iron Ore Lumps and Fines by using under

Keywords: BATAC Jig, Lump Ore BATAC Jig, Fine Ore BATAC Jig. INTRODUCTION Worldwide Iron Ore reserves seem to be quite vast but the grade of Iron Ore is depleting day by day. India is one such country which is blessed with high grade Iron Ore and for the last 50 - 60 years India is consuming and exporting it vastly.

More

on Or Ir e Fines - nepia

What are Iron Ore Fines? Iron ore is a natural/raw material that is mined around the world. The material is processed to allow its use in the iron/ steel making industry. Initially, this involves crushing followed by screening to separate the ore into lumps and fines. If the iron content of the processed ore is >60% then it can be shipped ...

More

Iron ore fines - BIMCO

Description: Iron ore fines come from the natural raw iron ore through the process of mining, crushing and screening, where the iron ore is separated into lumps and fines. Iron ore is done in this fashion so that it can be used for the iron/steel making industry.

More

Impact of quality of iron ore lumps on sustainability of mining ...

2015年1月1日 Iron ore lumps quality ... for fine crushing and ... R.R.R., 2003. Ore mineralogy and its relevance for selection of concentration methods in processing of Brazilian iron ores. Miner. Process.

More

WASTE MANAGEMENT BY PELLETIZATION OF IRON ORES FINES

the iron ore demands of all the DRI or steel plants. The excessive fines generated from the iron ore crushing units are mostly going waste. To curb the shortage of iron ore and meet the ever increasing demand for steel i.e. 100 Mt by 2020 as indicated by the Steel Ministry, pelletization technology is the

More

The Sintering Process of Iron Ore Fines – IspatGuru

2013年3月9日 The Sintering Process of Iron Ore Fines. satyendra; March 9, 2013; 9 Comments ; flux sinter, Iron ore fines, self fluxing sinter, sinter, sinter machines, Stright line machine. circular machine, super fluxed sinter,; The Sintering Process of Iron Ore Fines. Sintering plants are normally associated with the production of hot metal in blast furnaces in

More

Iron Ore Prices - CLO, Fines, Lumps, Concentration Prices Today

2023年5月1日 Iron ore is integral to the steel-making process and one of the most sought after commodities in the world. Iron ores are rocks and minerals from which metallic iron can be extracted. There are four main types of iron ore deposit: massive hematite, which is the most commonly mined, magnetite, titanomagnetite, and pisolitic ironstone.

More

Improve lump/fines prediction by understanding porosity – Process

2018年4月16日 Upgrading processes in BIF-derived iron ore deposits: implications for ore genesis and downstream mineral processing. Applied Earth Science (Trans. IMM: Section B), 112(1), 89-95. Poliakov, A, Donskoi, E, Hapugoda, S and Lu, L, 2017. Optical image analysis of iron ore pellets and lumps using CSIRO software Mineral4/Recognition4.

More

Development of processing technology for beneficiation of lean iron ore

PDF On Jan 1, 2011, A. Vidyadhar and others published Development of processing technology for beneficiation of lean iron ore fines from Goa Find, read and cite all the research you need on ...

More

Characterisation and Processing of Some Iron Ores of

2013年12月11日 Lack of process characterization data of the ores based on the granulometry, texture, mineralogy, physical, chemical, properties, merits and limitations of process, market and local conditions may mislead the mineral

More

Iron ore fines - BIMCO

Description: Iron ore fines come from the natural raw iron ore through the process of mining, crushing and screening, where the iron ore is separated into lumps and fines. Iron ore is done in this fashion so that it can be used for the iron/steel making industry.

More

2C(1) Iron Ore

In Japan, the proportions of iron ores charged into the BF are, at present, 15% lump ore, 10% pellets, and 75% sintered ore. Thus, pretreated iron ores represent a large majority of the ore used. In the sintering process, fine ores 2-3mm in diameter are mixed with coke breeze as a fuel. Burnt limestone powder is used as a flux. These materials ...

More

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

2015年4月3日 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore. Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 8.5 % in basalt and gabbro.

More

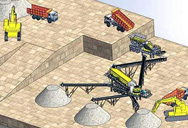

Iron ore crushing and screening process - SBM Ultrafine Powder

2022年8月3日 1. Iron ore crushing process: In the iron ore crushing process, the feeder, first crushing, secondary crushing, screening, fine crushing and dry selection are generally used. For the sake of economy, generally the finer the ore particle size entering the dry separator, the higher the proportion of iron-bearing ore that is dry selected.

More

(PDF) The utilisation of iron ore fines - Academia

The utilisation of iron ore fines : Technical options and challenges . × ... The present study deals with the utilization of fines generated from comminution process (crushing, ... better bed permeability etc. iv Pellets can be handled with ease than ore lumps or sinters.

More

Identification of working conditions and prediction of FeO content

2024年6月4日 The iron oxide (FeO) content had a significant impact on both the metallurgical properties of sintered ores and the economic indicators of the sintering process. Precisely predicting FeO content possessed substantial potential for enhancing the quality of sintered ore and optimizing the sintering process. A multi-model integrated prediction framework for FeO

More

Recent Trends in the Technologies of the Direct Reduction and

The blast furnace and direct reduction processes have been the major iron production routes for various iron ores (i.e. goethite, hematite, magnetite, maghemite, siderite, etc.) in the past few decades, but the challenges of maintaining the iron and steel-making processes are enormous. The challenges, such as cumbersome production routes, scarcity of metallurgical coke, high

More

Iron ore pricing explained - Fastmarkets

2018年6月7日 The sintering of fine ores can also be a polluting process, and mills under environmental constraints may favor direct-charge ore such as lumps or pellets. China’s 2016 update to its Environmental Protection Law enforces stricter caps on industrial pollution, and has increased the appetite for higher purity ores.

More>> Next:Comment Réduire Le Fer De Sable De Silice